UV-C IN FOOD SAFETY EU REGULATION 2024/1141.

The adoption of UV technology aligns seamlessly with the objectives of EU Regulation 2024/1141, offering a robust solution for meeting modern food hygiene standards. By integrating UV systems into their operations, food processors can ensure compliance while achieving greater efficiency and safety. UV technology will undoubtedly remain a cornerstone of innovative and sustainable hygiene practices as the food industry evolves.

BALANCING TRADITION AND SAFETY: THE EU DIRECTIVE 2024/1141.

The European Union has introduced Regulation (EU) 2024/1141, marking a significant update to hygiene standards for foods of animal origin.

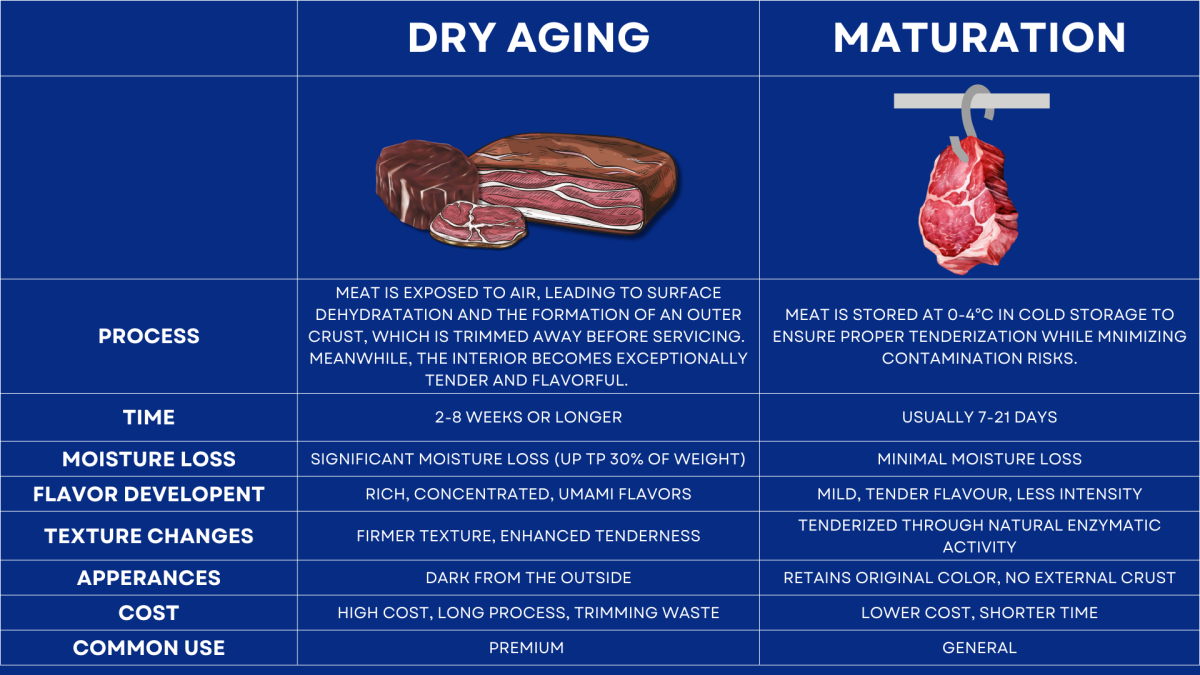

This directive reflects the EU's commitment to strengthening food safety, quality, and animal welfare across the food chain. The regulation introduces critical measures such as stricter conditions for beef dry aging, updates to marking animal products, and including sheep and goats under-regulated on-farm slaughter practices.

These changes aim to align traditional food practices, like dry maturation, with modern safety requirements while ensuring flexibility for producers and operators.

The European Food Safety Authority (EFSA), the EU's independent scientific agency for assessing food-related risks, guides these developments.

EFSA is pivotal in ensuring public health protection by providing evidence-based insights that underpin legislative decisions. With this directive, EFSA's evaluations of microbial risks, such as those associated with matured meats, have been instrumental in establishing the time, temperature, and transport parameters necessary to safeguard food safety without compromising traditional techniques.

Together, these efforts reflect the EU's strategic balance between food heritage, consumer protection, and regulatory progress.

Regulation 2024/1141: An Overview

The updated regulation introduces significant changes to the hygiene requirements for animal-origin foods, including meats, fish, dairy, and eggs. Key highlights include:

- New EU Marking System: The regulation replaces the existing CE marking with an EU identification mark for products of animal origin, aiming to streamline and standardize product labeling across the EU.

- On-farm and mobile Slaughter: The regulation expands on-farm slaughter to include sheep and goats under strict hygiene controls and specific conditions to safeguard animal welfare and public health.

- Carcass Transport Regulations, Refrigeration Conditions: New transport conditions limit carcass delivery to three slaughterhouses or a direct cold storage warehouse, with strict controls on temperature and journey time to maintain product safety; flexibility is introduced for transporting partially refrigerated carcass.

- Dry Aging of Beef: Specific rules have been introduced for the dry maturation (aging) of beef. The process is now limited to a maximum of 35 days, under controlled conditions of temperature and humidity to prevent microbiological risks. This aligns with EFSA's recommendations to ensure safety during prolonged aging processes.

- Transitional Periods: Operators must comply with rules regarding matured meat (e.g., dry aging) within six months, allowing for adaptation to the new regulations.

Europe accounts for approximately 30% of the global dry-aged beef market, second after North America. This growth is primarily driven by Europe’s strong culinary heritage, particularly in countries like France, Italy, Spain, and the UK, where dry-aged beef is highly appreciated in upscale dining.

However, challenges persist, such as high production costs due to specialized facilities, extended maturation times, and moisture loss, alongside limited shelf life and stricter regulatory compliance, as seen with the new Commission Delegated Regulation (EU) 2024/1141, which caps dry-aging at 35 days.

Reflecting broader trends, European consumers are embracing the philosophy of "less meat, but better meat," prioritizing quality over quantity due to health, sustainability, and ethical considerations. This shift is evident in a growing preference for premium products like, organic meats, and artisanal offerings emphasizing craftsmanship and traceability. Consumers increasingly associate high-quality meat with superior taste, nutritional value, and lower environmental impact, underscoring a cultural shift toward mindful, high-value meat consumption.

BALANCING FLAVOR, SAFETY, AND CONTROL IN DRY AGING.

The microbial risks in dry aging primarily stem from the surface exposure of meat to air over extended periods under controlled temperature and humidity conditions.

While the process enhances flavor and tenderness, it also creates an environment where microorganisms can grow.

1. Pathogenic Bacteria

- Listeria monocytogenes: A significant concern as it can grow at low temperatures commonly used in dry-aging (0-4°C)

- Escherichia coli (E. coli): Shiga toxin-producing strains, such as E. coli O157:H7, can contaminate meat surfaces during slaughter and persist if conditions allow.

- Salmonella: If hygiene practices are compromised, Salmonella can survive on meat surfaces, posing a risk of foodborne illness.

- Pseudomonas spp.: These bacteria thrive on meat surfaces exposed to air, leading to slime formation and off-odors.

- Molds and Mycotoxins: While some mold growth on dry-aged beef is natural and contributes to flavor, molds like Penicillium and Aspergillus can produce harmful mycotoxins if humidity and airflow are not adequately controlled.

Dry aging relies heavily on the conditions of the aging chamber, including temperature, humidity, and airflow. Any lapse in cleaning or sanitation of the chamber can result in bacterial or fungal contamination.

Poor air circulation can lead to uneven drying, creating microbial hotspots

4. Cross-Contamination

Improper handling during processing, aging, or cutting can transfer microorganisms to the meat surface. If hygiene protocols are not followed, pathogens like Listeria or E. coli may spread from tools, surfaces, or personnel.

MITIGATION STRATEGIES

While microbial risks are inherent in dry aging, carefully managing environmental conditions and hygiene practices ensures safety without compromising dry-aged beef's quality and unique characteristics.

.png)

Role of UV Technology in Food Safety

UV technology is a non-invasive, chemical-free method that inactivates pathogens by disrupting their DNA.

Integrating UV-C light into dry-aging processes helps maintain microbial stability while improving meat quality, aligning with the directive's focus on safe handling practices.

In the dairy and egg industries, UV treatment can serve as an alternative or complement to thermal pasteurization, adhering to HACCP principles required by the regulation. Similarly, fresh and thawed fish products benefit from UV treatment during processing, ensuring compliance with temperature and hygiene standards emphasized in the updated regulatory framework.

In light of Regulation 2024/1141, UV systems can address several requirements:

- Air Disinfection: UV-C devices can be installed in HVAC or, locally, inside the refrigeration units to mitigate microbial contamination.

- Surface Decontamination: UV devices effectively disinfect surfaces such as cutting boards, tools, and packaging materials, enhancing cleanliness in compliance with EU standards.

Dry aging demands strict conditions, including stable temperature, humidity, and consistent airflow. Air reuse in the dry-aging process is essential for maintaining precise environmental control and achieving energy efficiency, but it requires continuous cleaning to eliminate microbial contaminants.

Recirculating air through specialized HVAC systems ensures these parameters are maintained, promoting uniform drying of meat surfaces and preventing "hot spots" or excessive moisture that could foster microbial growth or uneven aging.

Reusing conditioned air significantly reduces the need for constant cooling and humidification, minimizing energy consumption and operational costs while upholding hygiene standards.

.png)

The updated Annex III of the EU Directive 2024/1141 highlights the importance of maintaining hygienic conditions during processing, storage, and transport, with UV-C light explicitly recognized as a reliable method for air decontamination.

To ensure safety, the recirculated air must be treated with advanced air filtration and disinfection technologies, such as HEPA filters or UV-C light.

While filters and UV-C technology are both effective in air treatment, UV-C often proves superior for applications like dry aging and microbial control in food processing environments due to its unique advantages:

.png)

IN ADDITION TO ITS MICROBIAL CONTROL BENEFITS, UV-C TECHNOLOGY SIGNIFICANTLY EXTENDS THE SHELF LIFE OF DRY-AGED MEAT BY REDUCING SURFACE CONTAMINATION AND MAINTAINING A CLEANER AGING ENVIRONMENT.

APPLICATION FOR A SUCCESSFUL IMPLEMENTATION OF UV-C.

.png)

HOW TO APPLY UV-C IN CENTRALIZED HVAC SYSTEM: COIL and AIRFLOW

.png)

Light Progress installation in a food industry ductwork.

Advanced Air Handling Units (AHUs) equipped with UV-C devices and sensors are designed to regulate temperature, airflow, and humidity, creating the precise environmental conditions required for processes like dry aging and cold storage.

When installed inside air ducts or at the final section of AHUs, UV-C devices form an effective UV-C barrier that inhibits the proliferation of harmful microorganisms by deactivating bacteria, mold, and viruses in the airflow.

A critical challenge in UV-C system design is accurately simulating the Real Dose of UV-C light delivered to the air, factoring in the dwell time—the duration air spends passing through the UV-C section of the AHU or duct system.

Light Progress addresses this challenge using specialized simulation software that tailors UV-C applications to specific conditions with high precision and confidence.

The software can quickly generate reliable outcomes by inputting key parameters, such as duct size and airflow rate, ensuring the system delivers optimal performance. These tools allow for accurate commissioning and validation of UV-C installations, ensuring effective microbial control while maintaining energy-efficient operations.

IN-ROOM UV-C APPLICATION: PRODUCTS SPECIFICALLY DESIGNED FOR DRY AGING ROOMS

Light Progress has been installing UV-C-specific devices for in-room air disinfection, such as UV-REFLEX-SCB or UV-FLOW, since the 1990s, offering decades of expertise in UV-C solutions for food hygiene.

These systems effectively reduce the airborne microbial load by leveraging forced air circulation within drying or cold rooms. By progressively eliminating bacteria, molds, and spores before they come into contact with food surfaces, they help maintain a clean and controlled environment. The result is improved product freshness, taste, and appearance, while minimizing common issues like weight loss and dehydration during processes such as dry aging.

For optimal performance, the system must be designed to treat as much indoor air as possible, with devices uniformly distributed throughout the space to avoid untreated areas, such as corners. Installation can be performed on ceilings or walls, ensuring comprehensive coverage and continuous air disinfection.

Light Progress installation in drying rooms

EU AND NORTH AMERICAN UV TECHNOLOGY TREND FOR MEAT PRODUCTS

While the EU Directive 2024/1141 explicitly highlights UV-C technology as a key tool for microbial control in processes like dry aging, the United States is also increasingly adopting UV-C solutions to enhance food safety.

Under FDA and USDA guidelines, advanced disinfection methods, including UV-C systems, are recognized for effectively reducing airborne and surface contamination, particularly in meat processing facilities. Although the regulatory approach in the US is less prescriptive compared to the EU's precautionary framework, the growing focus on HACCP compliance and technological innovation creates opportunities for UV-C to play a more prominent role in improving air quality, extending product shelf life, and supporting microbial safety standards across the food industry.

This trend highlights UV-C as a valuable, globally accepted solution for modern food safety challenges.

References:

**Commission Delegated Regulation (EU) 2024/1141**: Official document outlining updated hygiene standards for foods of animal origin, including specific guidelines for dry aging and microbial safety. (https://eurlex.europa.eu/legalcontent/EN/TXT/?uri=CELEX%3A32024R1141).

**European Food Safety Authority (EFSA)**: Scientific opinions and risk assessments related to microbial control, surface hygiene, and food safety measures in processing environments.[EFSA Publications](https://www.efsa.europa.eu).

**Air Handling Units and UV-C Technology**: Insights into the role of UV-C disinfection in HVAC systems, ensuring clean air circulation and microbial control for food processing facilities. [Eurovent Analysis on IAQ](https://www.eurovent.eu).

**Microbial Risks and UV-C Benefits in Dry Aging**: Industry reports and studies highlighting UV-C's role in reducing microbial load, extending shelf life, and improving product quality. (https://www.markwideresearch.com).

**Dry Aging Market Trends**: Reports analyzing European market growth, consumer trends favoring premium meat, and innovations in microbial safety technologies. [DataHorizzon Research Dry Aging Report](https://www.datahorizzonresearch.com)..