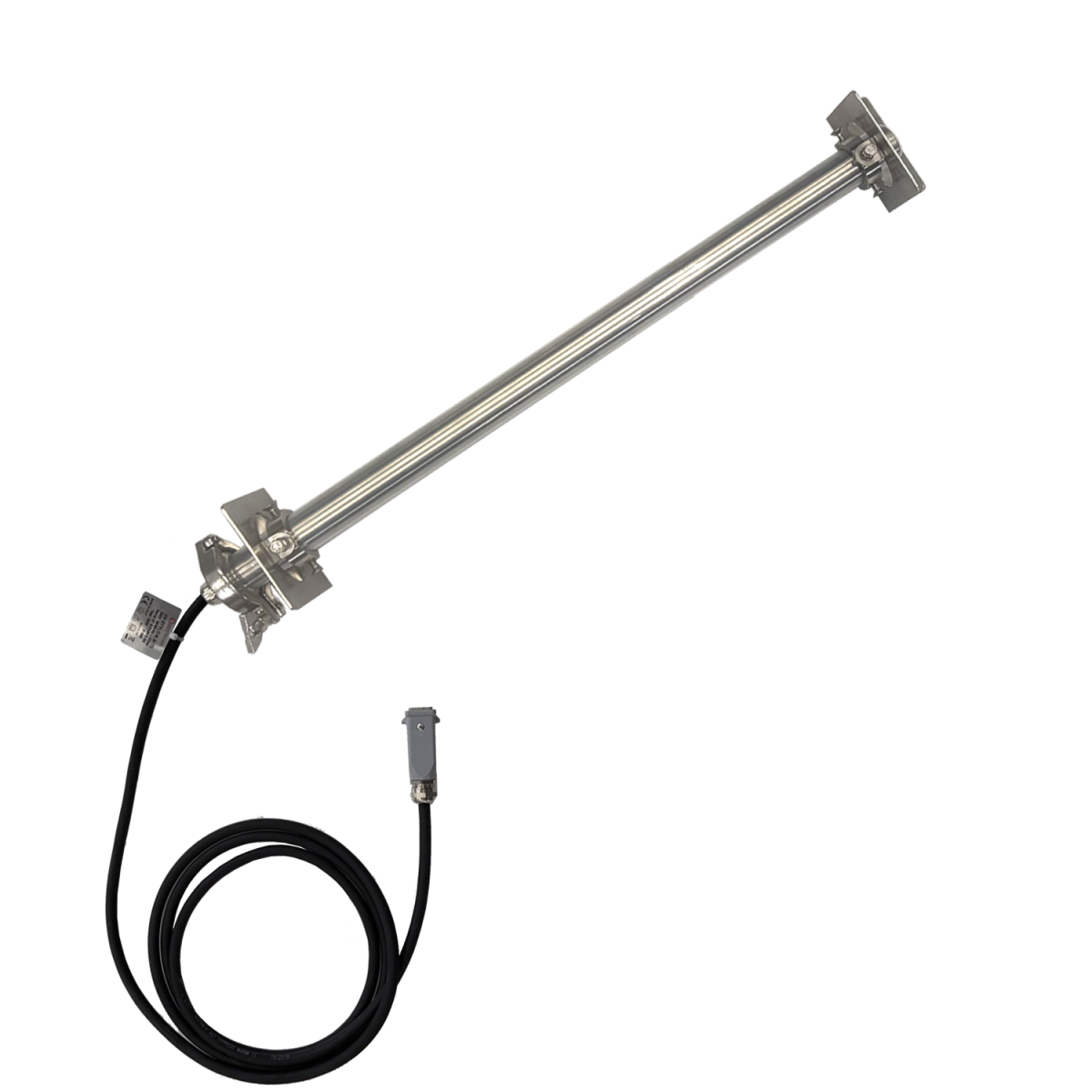

UV-STYLO-K is composed of:

a series of UV systems with the following features:

- One Lamp, Endless Applications; these single-lamp modules can fit easily in many different environments.

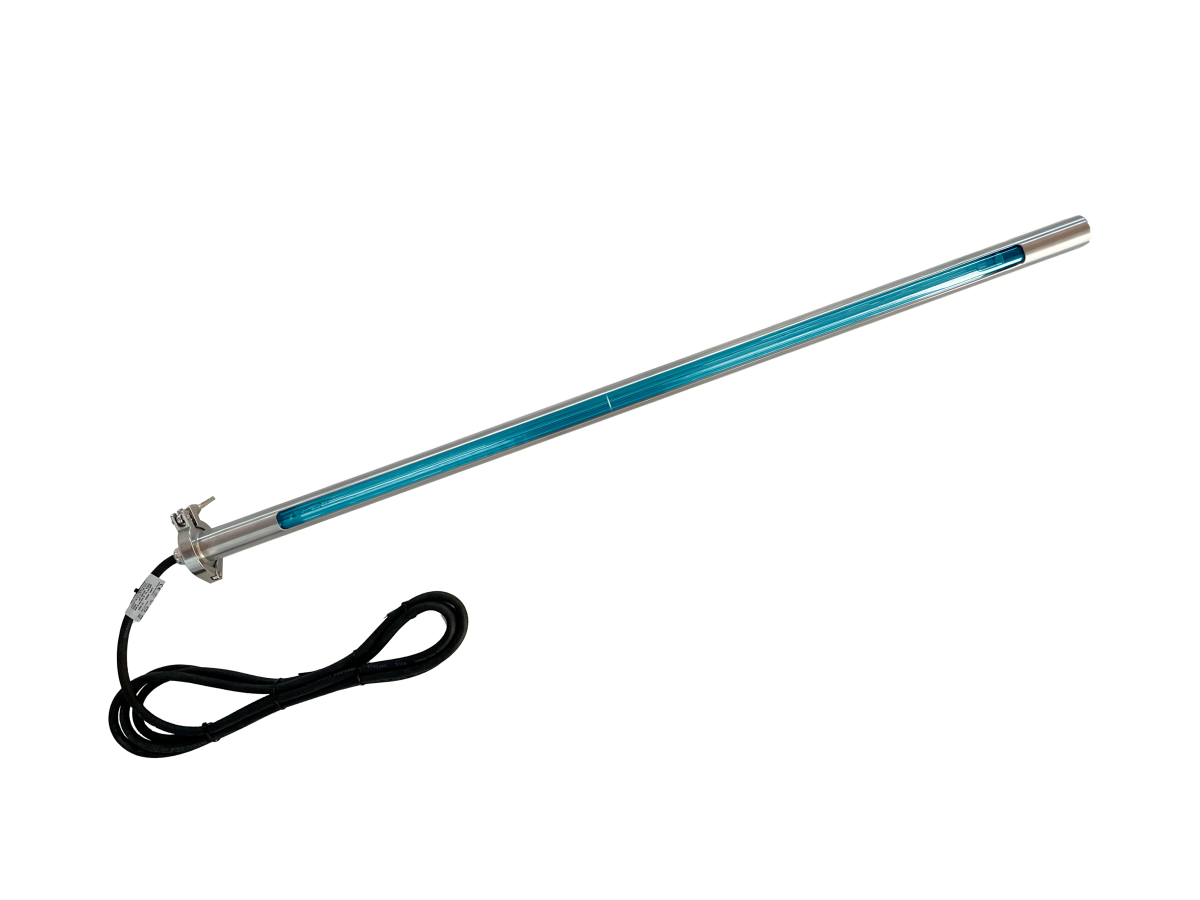

- Increased Disinfection Performance; with a High-Output UV-C lamp (253,7 nm) enclosed in a Quartz Sleeve, externally covered with UVLON™ the ultra-compact design features an internal coating of VEGA™ mirror-bright aluminum, ensuring maximum UV reflection for optimal results.

- Built to Last; with high-quality Stainless Steel AISI 304, all materials are tested to resist UV.

- Sealed Tight, Ready for the Fight; Complete protection against dust,(IP 69K) high temperature and high-pressure water jet cleaning.

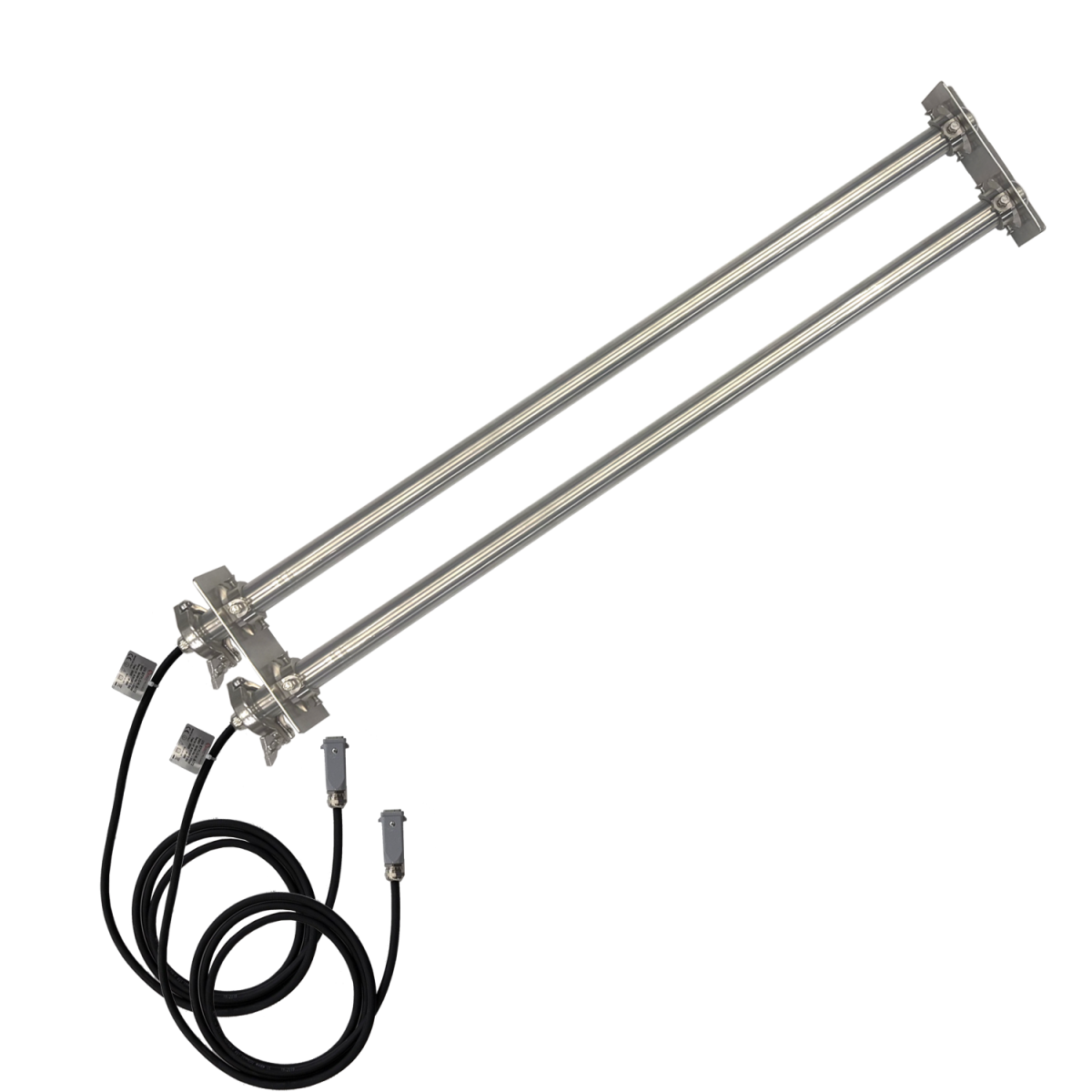

- Combine More Devices and organize them to build your disinfection solution.

- Choose the Best Power Supply options, from a simple open frame ballast to a separated control board available for advanced management of multiple lamps.

UV-STYLO-K

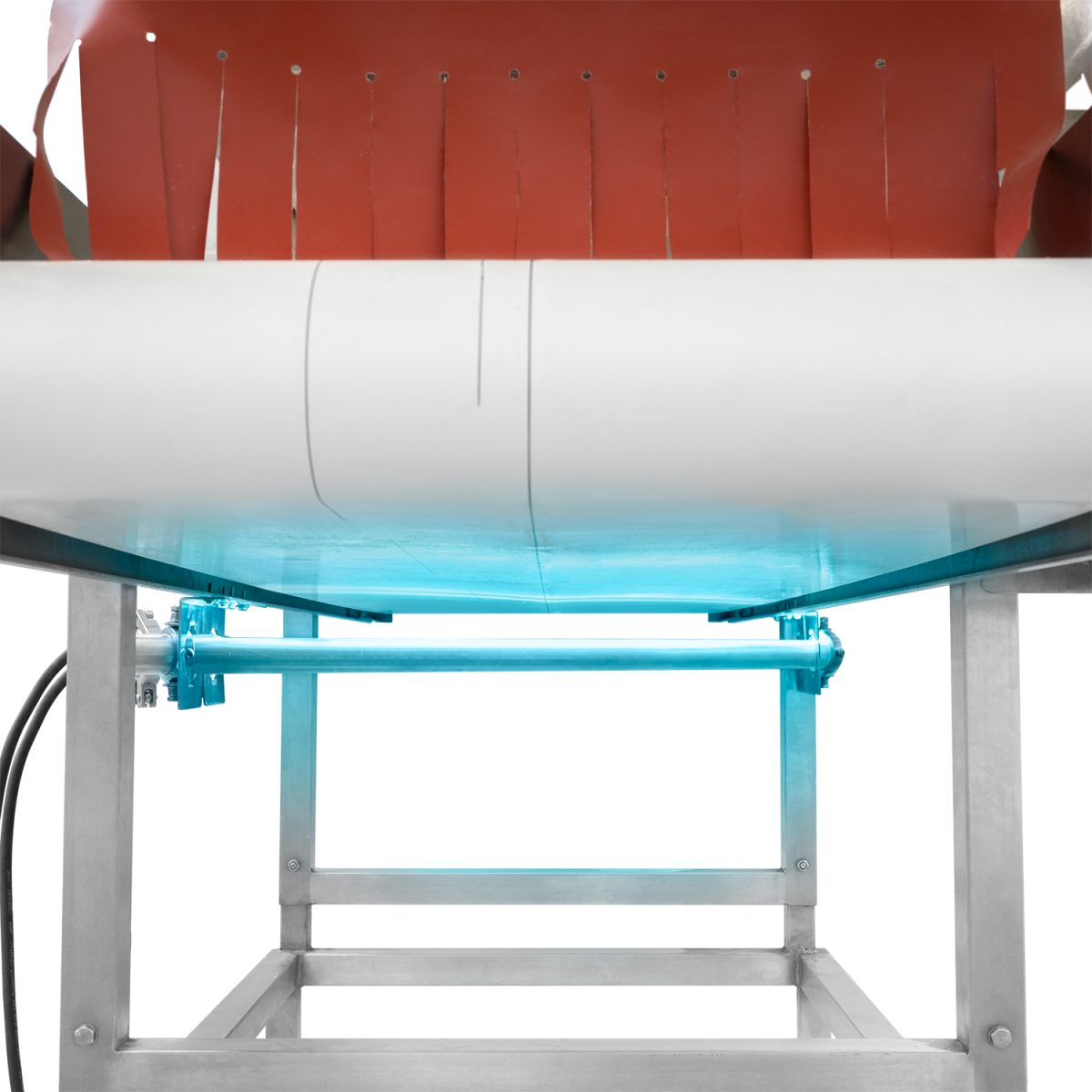

UV-STYLO-K is a versatile and effective UV system suitable for any transport and packaging line, including all types of conveyor belts, flow packs, thermoforming machines, cooling tunnels, automatic scales, and more.

Protected against aggressive and high-pressure cleaning cycles, including Clean-in-Place (CIP), EN 60529 (water jets at a pressure of 80 to 100 bar and a temperature of 80°C). UV-STYLO-K is widely used in food processing, research and development, pharmaceutical production, and microbiological laboratories.

All versions can be installed using a single or double stainless steel bracket, allowing one or more devices to be positioned together and seamlessly integrated into machinery. Additionally, the "tiltable" brackets enables the installation of the UVC system even on shorter belts.

Traditional cleaning methods are often insufficient to ensure high levels of hygiene, which can only be achieved through UV-C technology. In the food industry, hygiene levels must be monitored to maintain the high-quality standards required in this sector. It has been proven that increasing hygiene levels leads to an overall improvement in product quality. More specifically, UV-STYLO-K achieves a 99% reduction of bacteria such as Bacillus, Coli, Clostridium, Legionella, Vibrio, Salmonella, Pseudomonas, Staphylococcus, and more within just a few seconds of operation.

The high disinfection levels achieved by UV-STYLO-K are difficult to obtain through other means and would otherwise require the use of chemical compounds, which can be hazardous to health, harmful to the environment, and costly.

DISCOVER THE PRODUCTS

UV-STICK / UV-STICK (UL)

With UV-STICK, it is possible to achieve high levels of disinfection in a simple, immediate, and safe manner, without generating heat, without the use of liquids, and with no side effects, to maintain high hygiene and quality standards.

The device is installed like a regular ceiling-mounted light fixture and can be turned on during work breaks, always in the absence of personnel, to irradiate surfaces, which are then disinfected. In the environment, the natural circulation of air currents also allows for air treatment, which, purified of microbial load, creates an ideal and healthy environment.

UV-STICK-AL is made of aluminum, with an internal parabolic reflector in mirrored aluminum.

UV-STICK-AX is made of aluminum, with a flat internal reflector in mirrored aluminum.

UV-STICK-NX is made of stainless steel, with a flat internal reflector in mirrored aluminum. Also available in -UL version.

The disinfection level with UV-STICK achieves a reduction (99%) of bacteria such as Bacillus, Coli, Clostridium, Legionella, Vibrio, Salmonella, Pseudomonas, Staphylococcus, etc., in just a few minutes of operation.

UV-REFLEX series

UV-REFLEX ensures full compliance with the specific measures regarding "dry ageing" as provided by Delegated Regulation (EU) No. 1141/2024, which amends Regulation (EC) No. 853/2004.

With the use of UV-REFLEX, in particular, an improved maturation, ageing, aspect and quality of the meat is achieved. The treatment takes place by exploiting the constant forced air circulation, (due to the flow generated by the fan of the ventilation system), which pass next to the device and is decontaminated from microbes, before they enter into contact with the products inside the cold rooms.

The device does not affect the normal aging of the product, as it avoid only the growth of unwanted microorganisms, i.e. those found in the air.

UV-REFLEX can stay on continuously without any problem, so it ensures a level of microbial load always under constant control without the ups and downs, typical of traditional disinfection systems.

Owing to the use of the UV-C technology, it is possible to increase the shelf life of food preserved in cold rooms, without developing resistant microorganisms and without the use of chemicals, risky to employ and hard to biodegrade. UV-C treatment is dry and cold, does not alter the organoleptic features of food and its quality, but rather, it prevents product loss due to the proliferation of bacteria and fungi and enhances the freshness, taste and appearance of food, without dehydration and weight loss.

UV-REFLEX achieves the elimination (99%) of bacteria such as Bacillus, Coli, Clostridium, Legionella, Vibrio, Salmonella, Pseudomonas, Staphylococcus, etc. in just a few minutes of operation.

UV-TEAM

UV-STYLO-NX | UV-STYLO-A-NX

Traditional cleaning methods are, often, not sufficient to ensure high levels of hygiene, which can be achieved only by the use of UV-C technology.

As a matter of fact, food processes have the need to be controlled, by monitoring hygiene levels, to keep quality standards, typical of this sector, high.

It is shown how, in the food industry, the increase in hygiene level allows a consequent and general product quality increase and, more specifically, UV-STYLO-NX achieves the abatement (99%) of bacteria such as Bacillus, Coli, Clostridium, Legionella, Vibrio, Salmonella, Pseudomonas, Staphylococcus, etc. in just 4 minutes of operation.

High disinfection levels of UV-STYLO can be otherwise achieved and only with the use of chemicals, hazardous to health and harmful to the environment, as well as costly.

UV-TEAM-A

It is shown that the control and the increase of hygiene level allows a consequent and general increase in quality both in healthcare facilities but also in pharmaceutical sector, in microbiological laboratories, etc.

The disinfection level with UV-TEAM-A achieves the elimination (99%) of bacteria such as Bacillus, Coli, Clostridium, Legionella, Vibrio, Salmonella, Pseudomonas, Staphylococcus, etc. in just a few minutes

of operation.

Some application examples are treatment in bottling lines and the down channel plugs; treatment of products being placed on the clean room (using a UV tunnel that allows you to enter products in protected environments by eliminating any risk of contamination) treatment of spices (tunnel with Shaving system thin layer, reduction of the bacterial load and increase the shelf-life.

The - A serie includes special amalgam lamps. This type of bulbs, unlike the standard low pressure UV-C lamps, use a special “amalgam” made with metals, which optimize the UV germicidal power efficiency.

Amalgam systems allows triple the UV-C emission compare to a low pressure lamp with the same length, and up to 16.000 hours life that

guarantee a consequent cost saving.

Amalgam lamps are perfect in application where there is a short timing of exposition, such as in some food packaging lines.

High disinfection levels of UV-TEAM can be otherwise achieved, but only with chemicals, hazardous to health and harmful to the environment, as well as costly.

UV-STYLO-F

UV-STYLO-F is designed specifically for applications in the food industry, and that is why one of its features is also the IP67 protection level, allowing it to combine perfectly with damp environments and water splashes.

Traditional cleaning methods are, often, not sufficient to ensure high levels of hygiene, which can be achieved only by the use of UV-C technology.

As a matter of fact, food processes and storage have the need to be kept under control, by monitoring hygiene levels, to increase quality standards, which are usually very high.

It is shown how, in the food industry, an increased hygiene level allows a consequent and general product quality improvement. UV-STYLO-F achieves the elimination (99%) of bacteria such as Bacillus, Coli, Clostridium, Legionella, Vibrio, Salmonella, Pseudomonas, Staphylococcus, etc. in just a few minutes of operation.

High disinfection levels of UV-STYLO-F can be otherwise achieved but only with a massive use of chemicals, hazardous to health and harmful to the environment, as well as costly.

UV - TEAM-A-4P

It is shown that the control and the increase of hygiene level allows a consequent and general increase in quality both in healthcare facilities but also in pharmaceutical sector, in microbiological laboratories, etc.

The disinfection level with UV-TEAM-A-4P achieves the elimination (99%) of bacteria such as Bacillus, Coli, Clostridium, Legionella, Vibrio, Salmonella, Pseudomonas, Staphylococcus, etc. in just a few seconds of treatment.

Some application examples are treatment in bottling lines and the down channel plugs; treatment of products being placed on the clean room (using a UV tunnel that allows you to enter products in protected environments by eliminating any risk of contamination) treatment of spices (tunnel with Shaving system thin layer, reduction of the bacterial load and increase the shelf-life).

The UV-TEAM-A series includes special amalgam lamps. This type of bulbs, unlike the standard low pressure UV-C lamps, use a special “amalgam” made with metals, which optimize the UV germicidal power efficiency. Amalgam systems allows triple the UV-C emission compare to a low pressure lamp with the same length, and up to 18.000 hours life that guarantee a consequent cost saving.

Amalgam lamps are perfect in application where there is a short timing of exposition, such as in some food packaging lines.

High disinfection levels of UV-TEAM-A-4P can be otherwise achieved, but only with chemicals, hazardous to health and harmful to the environment, as well as costly.