Great food smells amazing—but not on your clothes.

If lingering odors and VOCs create discomfort for customers and staff, UV-FAN provides a powerful solution. It purifies the air, reducing unwanted smells and improving comfort for everyone.

CHALLENGES

La Cocinona is a vibrant kitchen in the heart of Madrid, dedicated to preparing high-quality takeaway food. Its central location makes it easily accessible, but also presents challenges in managing airflow within a compact space. During cooking hours, heat and aromas build up inside the premises, leading to the frequent need for ventilation by opening the doors. This creates a dynamic air exchange between the kitchen and the street, influencing indoor comfort for both staff and visitors.

What is in the air?

(VOCs) like formaldheide are released during cooking, along with smoke, grease particles, and humidity. Heat and air circulation spread these compounds, making odors linger on surfaces, fabrics, and in the air.Proper ventilation and air purification help manage these airborne elements, ensuring a fresher environment.

PROPOSED SOLUTION

To maintain a pleasant atmosphere, La Cocinona has implemented various ventilation solutions, including ozone generators. However, balancing effective airflow while ensuring an optimal indoor environment remains a key focus. Opening the doors for ventilation can lead to air circulation challenges, affecting both the workspace and the surrounding area. Following a thorough analysis of La Cocinona’s layout, ventilation system, air circulation, and particle levels, the installation of 4 UV-FAN units was recommended to enhance air quality and reduce odors.

These units are strategically placed based on key factors such as odor sources, airflow patterns, and room volume:

1 - Entrance corridor – to address air movement at the main access point

2 - Storage/Fryer area – where cooking emissions are most concentrated

3 - End of the entrance corridor– to reinforce air purification along the airflow

4 - Rotisserie section –another significant source of airborne particles

Each UV-FAN unit is equipped with an hour counter, allowing for precise tracking of operating hours and timely lamp replacements, ensuring consistent performance. Additionally, the air conditioning system has been reviewed and found to be adequate, confirming that the proposed solution integrates effectively with existing ventilation.

In addition to the UV-C lamps, UV-FAN also contains an innovative titanium dioxide nano-particle filter, TiOx®, which enhances the germicidal action with additional odor control.

Let your clients enjoy their meal in a fresher atmosphere, work more efficiently, spend less time on cleaning, and provide a wonderful experience for all.

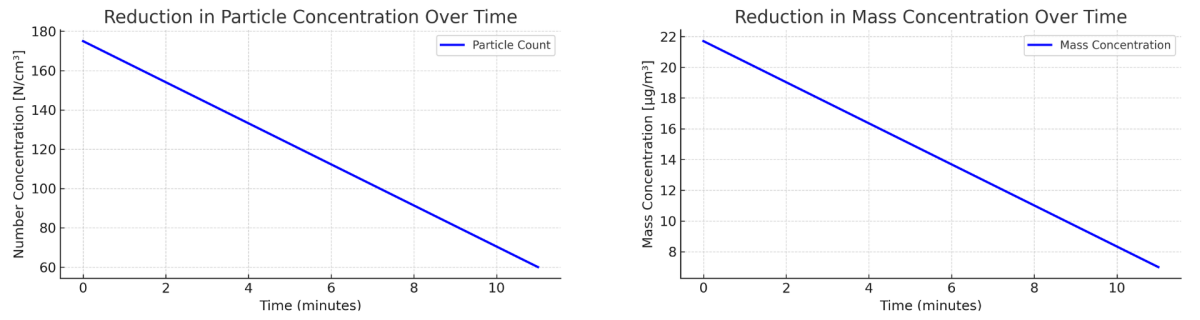

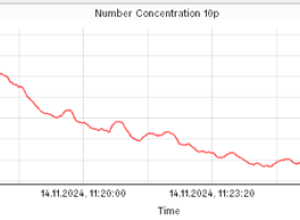

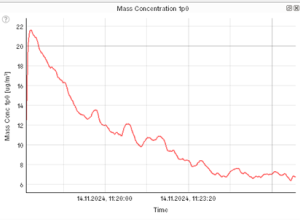

During the pilot test, when the entrance door remained closed for 11 minutes (from 11:17 to 11:28), a significant reduction in airborne particles was observed due to the operation of the air purifier:

- Particle count reduction: From 175 to 60, a 65.7% decrease

- Particle mass reduction: From 21.7 to 7 units, a 67.7%

These results confirm the air purifier's effectiveness in rapidly improving air quality by significantly reducing airborne particulates in just 11 minutes.

These results were measured using a instrument for IAQ, confirming the purifier’s ability to significantly reduce airborne particulates and rapidly enhance air quality.

BENEFITS

1- Cleaner Surfaces

Less frequent wall cleaning and reduced floor slipperiness by lowering airborne grease buildup.

2- Fresher Work Environment

Minimized odors on work clothes and improved air quality, reducing irritation and discomfort..

3- Better Airflow Management

Fewer ventilation needs while maintaining a fresh indoor environment.

4- Effective Odor Control

Reduced odors inside and on Bolivar Street for a cleaner, more pleasant atmosphere.

5- Seamless Integration

Easy to retrofit with no need for disruptive installation, ensuring quick and hassle-free implementation..

We would like to extend our sincere thanks to RecoveryLand team for partnering with us on this case study, assisting the client, and making this valuable test possible.

We encourage others to reach out to the Light Progress team to explore and test our UVC solutions to enhance your environment.